30 Duke Street St James's facade - circulatory applications by Elliott Wood (courtesy of GPE).

Achieving these targets was an important part of the brief set by our client, GPE, from the outset. The sustained commitment of GPE, as well as Mace, the main contractor, was key, particularly in navigating the complex challenges of logging, testing and storing the reclaimed materials. Our early groundwork, together with their long-term backing, embedded re-use into both the enabling works and the final design, demonstrating how circular economy can shape the way we think about construction.

Prefabricated facade panels being installed on site, August 2025 - managed by Mace.

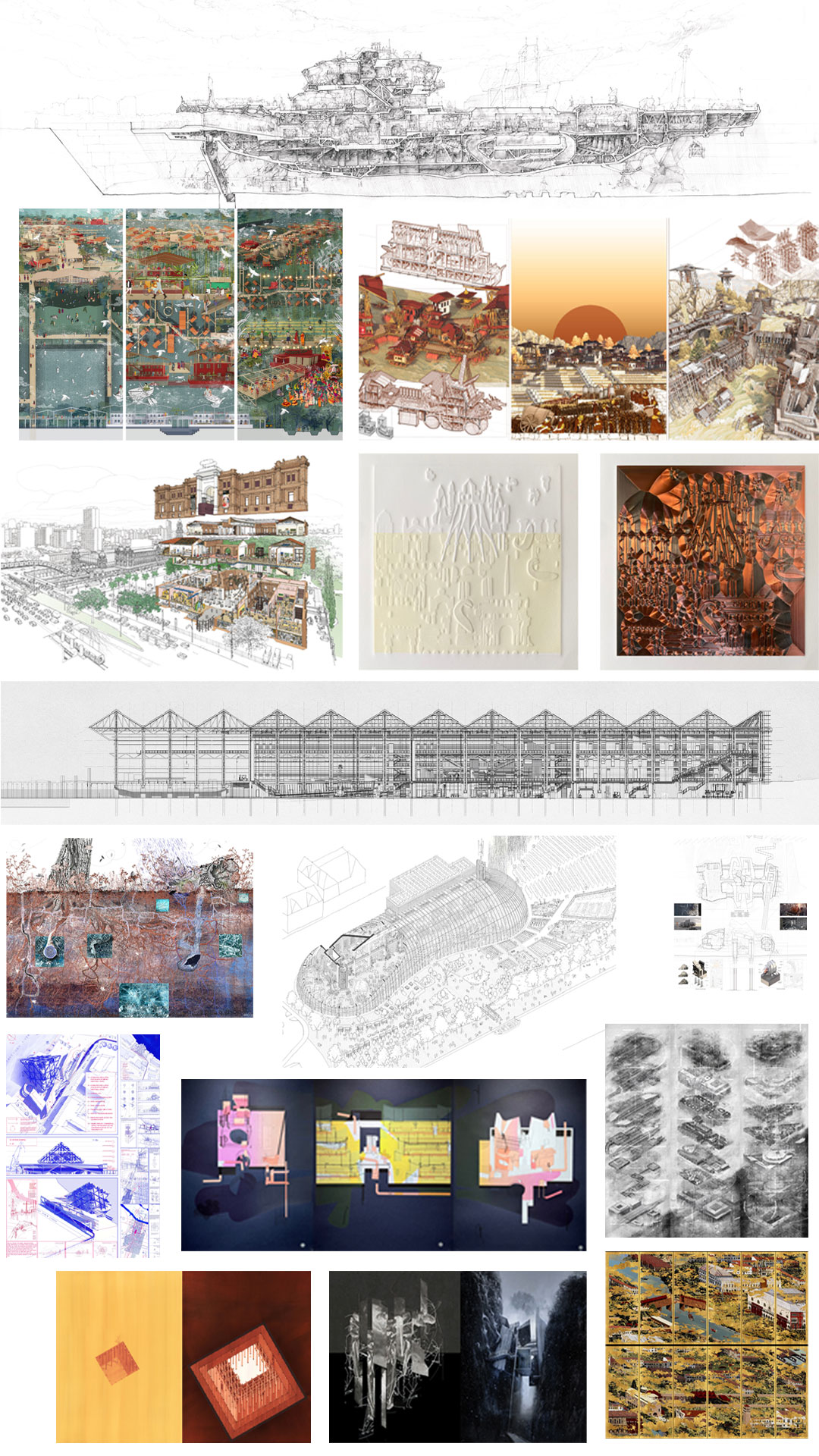

One of the most striking elements of our new facade is its Portland stone components, which we reclaimed directly from the original buildings on site. We were able to recover and repurpose 17% of their original stone, avoiding the need to excavate and transport almost 62,000kg of new material.

Salvaging the stone and granite from the buildings’ exterior required us to adapt the facade articulation to suit existing dimensions, which meant constant design coordination as survey data evolved.

Installation of prefabricated facade panels, August 2025 – managed by Mace.

Our facade design is also setting new standards for circular innovation. The scheme includes the UK’s first commercial application of Hydro CIRCAL 100R aluminium, manufactured entirely from 100% recycled post-consumer scrap and integrated into the window frames in collaboration with OAG and Mace. This move alone is expected to save 82 tonnes of CO₂ equivalent compared to conventional aluminium.

Additionally, the project is the first commercial development in London to use ORAÉ® glass, which is low-carbon glass made from recycled content, with the recycled glass reintroduced into production rather than sent to landfill.

Prefabricated facade bay fabricated off site, May 2025.

Many of these innovations have been made possible through off-site manufacturing. For example, Make, FMDC and Mace partnered with OAG and Grants to fabricate window systems that combine Hydro CIRCAL frames and ORAÉ® glass directly into doughnut precast panels before delivery to site – a move that has significantly reduced material use and waste and simplified installation.

The zinc-clad dormers were also prefabricated, in partnership with AMR, reducing carbon emissions, improving quality and minimising disruption at site.

30 Duke Street facade, September 2025.

By embedding circular design principles into this new-build commercial project, we’ve challenged ourselves to reduce its carbon impact through new approaches to material salvage and re-use. 30 Duke Street St James’s illustrates our commitment to rethinking how buildings are designed, built and valued. Crucially, it shows that sustainable construction doesn’t mean compromising on quality or performance.